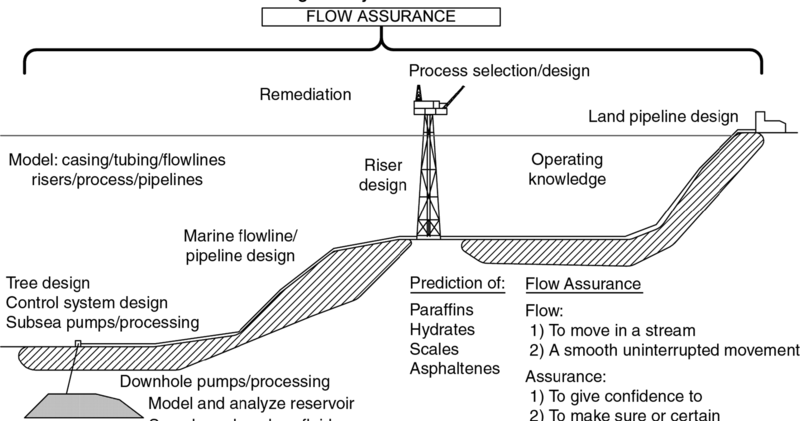

Understand offshore flow assurance challenges including hydrate formation, wax deposition, thermal control, and mitigation strategies in subsea pipelines.

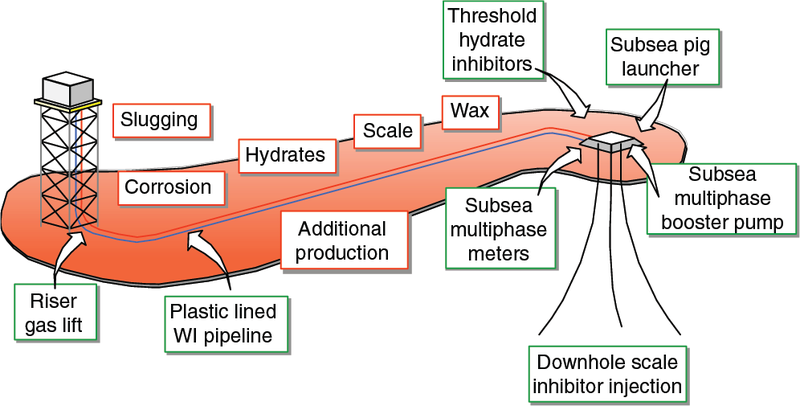

Flow assurance ensures reliable, continuous hydrocarbon transport from subsea wells to processing facilities or export points in offshore and deepwater environments. Low seabed temperatures (~4°C), high pressures, long tieback distances, and multiphase flows create severe threats: hydrate formation, wax deposition, and thermal instability. These issues can cause blockages, reduced throughput, pressure spikes, gelation during shutdowns, and expensive interventions.In 2026, deepwater projects (Gulf of Mexico, Brazil pre-salt, West Africa, North Sea) increasingly face these challenges with longer tiebacks and HPHT fluids. This article covers the mechanisms, risks, and current mitigation strategies for hydrates, wax, and thermal instability in offshore pipelines.

1. Hydrate Formation & ManagementHydrates are ice-like solids formed when light hydrocarbons (methane, ethane, propane) combine with free water under high pressure and low temperature. In subsea pipelines, hydrates form during:

- Shutdowns and restarts (cool-down below hydrate formation temperature)

- Low flow rates or transient conditions

- High water-cut production

Key Risks:

- Rapid plug formation (hours to days), leading to complete blockage.

- Deepwater exacerbates risk due to high hydrostatic pressure and cold ambient conditions.

Prevention & Mitigation Strategies (2026 Best Practices):

- Thermal Management — Passive insulation (pipe-in-pipe, syntactic foam) to maintain fluid temperature above hydrate formation curve. Active heating: direct electrical heating (DEH) or trace-heated pipe-in-pipe for cold start-ups and extended shutdowns.

- Chemical Inhibition:

- Thermodynamic inhibitors: monoethylene glycol (MEG) or methanol to shift hydrate equilibrium curve.

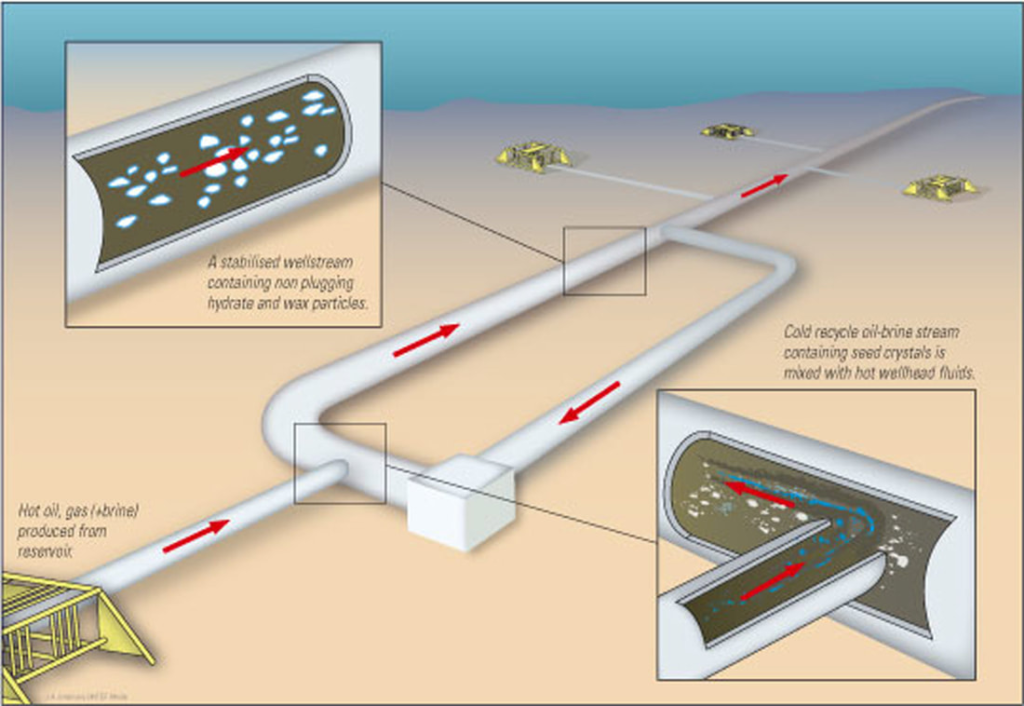

- Low-dosage hydrate inhibitors (LDHI): kinetic inhibitors (delay nucleation/growth) and anti-agglomerants (allow hydrate slurry transport).

- Operational Controls: Depressurization during shutdowns, continuous MEG injection, pigging to remove water accumulations.

- Monitoring: Fiber-optic distributed temperature sensing (DTS) for real-time temperature profiling and early hydrate detection.

Hydrate formation envelope diagram showing pressure-temperature conditions where hydrates form critical for offshore pipeline design.)

2. Wax Deposition & ManagementWax (paraffin) deposition occurs when heavy hydrocarbons crystallize as oil cools below its wax appearance temperature (WAT). In subsea pipelines, cooling from hot reservoir fluids to cold seawater drives wax buildup on pipe walls, reducing diameter and flow capacity.

Key Risks:

- Gradual restriction → increased pressure drop and reduced production.

- Severe deposition causes gelation during shutdowns (restart difficulties).

- Wax can stabilize hydrate slurries, increasing plug risk.

Prevention & Mitigation Strategies:

- Thermal Management: Insulation or active heating to keep bulk fluid above WAT.

- Chemical Inhibition:

- Pour point depressants (PPDs) and wax crystal modifiers to alter crystal structure and prevent adhesion.

- Solvent treatments (xylene, toluene) for periodic cleaning.

- Mechanical Methods: Regular pigging (mechanical, gel, or chemical pigs) to scrape wax from walls.

- Design Optimization: Larger pipeline diameter, optimized insulation, chemical dosing based on WAT and wax content.

- 2026 Trends: Non-intrusive monitoring (thermal profiling using production heat) and AI-based deposition prediction to optimize pigging frequency.

(Cross-section schematic showing wax deposition buildup in a subsea pipeline.)

3. Thermal Instability & Integrated Flow AssuranceThermal instability refers to temperature-related variations that trigger or worsen flow assurance issues:

- Rapid cooling during shutdowns (hydrate/wax risk)

- Thermal gradients causing slugging or instability in multiphase flow

- HPHT fluids cooling from reservoir temperature (>350°F) to seabed conditions

Integrated Management:

- Steady-State & Transient Modeling: Tools like OLGA, Pipesim, or LedaFlow simulate temperature profiles, hydrate/wax envelopes, and restart scenarios.

- Thermal Retention: Pipe-in-pipe (PIP), bundle systems, burial, or rock cover to minimize heat loss.

- Active Heating: DEH for hydrate prevention and wax management during cold restarts.

- Chemical & Mechanical Synergy: Inhibitors + pigging programs.

- Monitoring & Digitalization: Fiber-optic DTS/DAS for real-time temperature/strain/leak detection; AI/ML models for predictive risk assessment and optimized chemical dosing.

(Schematic of offshore pipeline flow assurance with hydrate, wax, and thermal management strategies.)

ConclusionFlow assurance in offshore pipelines requires an integrated approach combining thermal management, chemical inhibition, mechanical intervention, and real-time monitoring. Successful management minimizes unplanned shutdowns, maximizes production uptime, and reduces OPEX in deepwater and HPHT developments.For practical tools—including hydrate risk checklists, wax deposition calculators, and flow assurance planning templates—visit the free downloads section at OffshorePipelineInsight.com.

Oko Immanuel

Subsea & Offshore Pipeline Engineer | Former Roughneck | Texas A&M Petroleum & Subsea Engineering Alum

Meta Description: Expert guide to flow assurance in offshore pipelines: managing hydrate formation, wax deposition, and thermal instability with thermal, chemical, and mechanical strategies for 2026 deepwater operations.